I have a concrete floor in my studio. I also have flat feet, thus I need really good floor mats in my studio. Over the years I have tried lots of different options for floor mats.

I tried the cheap ones from Home Depot, etc. When they were not soft enough, I tried stacking up the cheap ones, etc. I even let someone at a AAW symposium talk me into a really expensive $200 mat. A sucker is born every minute! I hate that mat with a passion! It will not stay put! It is always sliding out of position! Err!!!

A few years ago I decided to change all of my mats to the expensive kitchen mats with holes from Rubber-Cal. If they are good enough for chiefs who stand on them all day in the kitchen then they are good enough for me.

I like the “Rubber-Cal Dura-Chef Interlock Anti-Fatigue Rubber Matting, 5/8″ x 36″ x 36”.

It has to be the 5/8″ thick mat! The 1/2″ and 3/8″ thick ones are not soft enough. The 3/8″ thick one is a complete and total waste. It is like standing on concrete.

Get from Amazon with a Prime Membership!

Often there are similar looking mats at Home Depot, etc. At first I was buying my mats their. Then they changed brands. The new brand really sucked! The rubber was to hard! Not enough cushioning for my flat feet.

Often there are similar looking mats at Home Depot, etc. At first I was buying my mats their. Then they changed brands. The new brand really sucked! The rubber was to hard! Not enough cushioning for my flat feet.

Then I discovered I could get the mats on Amazon and the shipping was FREE with my Amazon Prime membership! Otherwise, the shipping will kill you! The mats are really heavy.

Do NOT purchase directly from Rubber-Cal. The shipping will kill you! Free shipping from Amazon with Prime membership is like the best deal on the face of the earth!

The mats from “Rubber-Cal” come and go on Amazon. With a price around $25 each. Right now (12/18/2019) they are on Amazon for $30 each. A good price! Beware! Some times the price goes up to $50 each or more. Wait a while and the price will go back down.

Well, maybe $30 is not such a good price. But, I have flat feet. It is worth it for me. Similar mats at Home Depot, etc. have gone up in price over the years. They are getting close to $25.

Also beware of Amazon’s dynamic pricing. If you purchase something today . Then go back to purchase more in a few days then Amazon with jack up the price. You can sometimes avoid this by looking up your old order. Then going to old order. Then go to the item from the old order. Now the price is the same?

Other Sizes, Etc

Rubber-Cal makes smaller and larger versions of the same mat. The 36″ x 36″ ones are really heavy. A handful to move. Thus I would not go with a larger mat.

I like the mats that lock together with tabs rather than the ones with fancy beveled edges. I just let the tabs hang off at the end of a run of mats. I have no problems with walking or tripping over the tabs. I don’t need beveled edges.

This is really important so I am going to repeat it. It has to be the 5/8″ thick mat! The 1/2″ and 3/8″ thick ones are not soft enough.

Taking Up the Mats

The mats are heavy. Taking the all up and putting them back is a huge job! This has not really been a problem.

The mats are heavy. Taking the all up and putting them back is a huge job! This has not really been a problem.

I only take up the mats when I absolutely have to move a big stationary tool .

I DO NOT take them up for cleaning!

Cleaning

Yea all those hole catch wood chips and saw dust like crazy! I avoided these mats for a long time. I wanted a smooth top mat that would be easy to clean!

Yea all those hole catch wood chips and saw dust like crazy! I avoided these mats for a long time. I wanted a smooth top mat that would be easy to clean!

In use I have found the holes actually help. The wood chips in the holes add to the cushioning.

Cleaning is not a huge problem if you are not to anal about it. Most of the time I just sweep the big wood shaving off the top. Sweeping is easy, no problem. Let the saw dust in the holes be! Live and let live.

When I want to get the mats really clean for classes, etc then I use by big 4″ vacuum hose attached to my big cyclone dust collector. It sucks the shavings out of the holes no problems in most cases. Let live any small stuff that gets stuck. It will come out next time.

Floor Coverage

I have a ton of mats. Lots of them. I purchased them little by little at first. Then I decided to cover all the area in my studio where their were no big stationary tools and I walked frequently.

I have a ton of mats. Lots of them. I purchased them little by little at first. Then I decided to cover all the area in my studio where their were no big stationary tools and I walked frequently.

You can’t put the mats under big tools like lathes. They are to soft. The tools will bounce around to much.

Entrance Mats for Studio

Long ago I installed similar mats in the hallway outside of my studio. See photo. It was one of the best things I ever did!

Long ago I installed similar mats in the hallway outside of my studio. See photo. It was one of the best things I ever did!

The idea here is these mats knock off any saw dust and shavings on the bottom of my feet BEFORE I track into the rest of the house. They work good.

I got the mats long ago. I have no idea where I got them or any other details.

]]>

I am looking for two new students!

I have 1 opening in my Tuesday classes and 1 opening in my Thursday classes starting in January of 2020. Matching the right lathe height to each person’s elbow height above the floor is very important.

The opening on Tuesdays is on my shorter lathe. I am looking for a person around 5′ 5″

The opening on Thursdays in on my taller lathe. I am looking for a person around 6′ 2′.

Dates

Any 10 out of 12 Tueday’s between January 14th and April 7th, 2020. (Jan 14, 21, 28, Feb 4, 11, 18, 25, Mar 3, 17, 24, 31, Apr 7, 2019 (No class Mar 10)

OR

Any 10 out of 12 Thursday’s between January 16th and April 9th, 2020. (Jan 16, 23, 30, Feb 6, 13, 20, 27, Mar 5, 19, 26, Apr 2, 9, 2019 (No class Mar 12)

Class Information

For more class info you read my PDF here:

http://www.carlford.info/pages/calendar/images/2019/my_ww_class_details_2020.pdf

Or you can get in on the web here:

http://www.carlford.info/pages/calendar/calendar.html

Sign Up

If you are interested in taking a class please email me at [email protected]

]]>

I am now using sandpaper rolls from Klingspor for all of my hand sanding. Rather than “Porter Cable Stikit Sandpaper”. I still like the Stikit paper but it is to hard to get.

• I like “Klingspor Abrasives 4.5″x 10 Meter (33′) Pressure Sensitive Adhesive, Paperbacked Roll, xxx Grit, Stearated Aluminum Oxide”. Item # AR330xx. AR33008 for 80 grit, etc. Around $18 per roll on 12/2019.

I purchased several different rolls of stuff from Klingspor. I decided I liked the above the best. It is very similar to the “Porter Cable Stikit Sandpaper” that use to be my favorite.

“Klingspor Abrasives Stearated Silicon Carbide, 4-1/2″x 10 Meter (33′) PSA Roll, 180 Grit, Porter Cable Stickit” is ok. Item #AR136xx. It is cheaper at $14 per roll. But, I don’t like it as much. The paper seems to be a little stiffer.

• I have 80, 120, 180, and 220 grits.

• I have 80, 120, 180, and 220 grits.

I get it from “Klingspor’s Woodworking Shop”.

I generally do not sand beyond 220 grit. If I do sand beyond 220 then I use 6″ Abralon pads by Mirka.

For more info see my “Great Polyurethane Finishes” handout at http://www.carlford.info/pages/demos_classes/great_poly_finish/Great_Poly_Finish.pdf

• I like to cut up the sandpaper into small sheets in advance and store it in “Large Binder Clips” (aka large paper clips). For more info see “Spindle Turning Sandpaper” section in my “Handy Sandpaper” blog entry.

Notes:

1. I use to use “Porter Cable Stikit Sandpaper”. My old “Stikit Sandpaper” blog entry is now obsolete. It is replaced by this new blog entry.

2. I use Blue Flex disks for all of my power sanding. See my Blue Flex Sanding Disks blog entry.

3. I have eliminated 150 grit from my sanding. I decided it is to close to 120 grit. Just a waste of time. I sand 80, 120, 180, then 220.

Don Pencil is no longer in business. Thus I now suggest you get the following from Packard Woodworks (www.packardwoodworks.com)

– 1-1/4″ x 8 Lathe Buffing Extender #120952

– 8″ Wax Beall Replacement Wheel #123940W

– 4″ Wax Beall Bowl Buff #123934W

Note: I attach the Buffing Wheels to Long Buffing Adapter with a local hardware store 3/8” bolt and fender washers.

I don’t use any wax on my buffing wheels! Thus I just get the Beall wheel. NOT the complete system! See “Great Polyurethane Finishes Demo” (http://carlford.info/blog/2013/01/great-polyurethane-finishes-demo/) for more info.

Or you can get the 8″ Wheel from Mcmaster-Carr (www.mcmaster.com). Two of “Buffing Wheel for Curved Surfaces, 8″ Diameter x 1/2″ Thick, 1/2″ Arbor Hole” #4820A12.

Or you can get the 8″ Wheel from Mcmaster-Carr (www.mcmaster.com). Two of “Buffing Wheel for Curved Surfaces, 8″ Diameter x 1/2″ Thick, 1/2″ Arbor Hole” #4820A12.

https://www.etsy.com/shop/carlfordwoodturner/

My high quality pieces are priced to sell! You win because I have a lot of pieces that I want to sell!

I am going to add more stuff over the next couple of days. Then I hope to add 2 new pieces per week.

There are also never seen before pictures of my stuff.

]]>

I have found that using a 2-1/2″ diameter hole that is 1/4″ deep is a good way to mount blanks for plates and shallow bowls on the lathe. It is easy and very secure.

It’s a lot better than using a chuck screw. Because chuck screws and shallow holes don’t mix well.

I drill a 2-1/2″ diameter hole that is 1/4″ deep with a Forstner bit. Then expand my 4 jaw chuck into the hole.

You need to be careful when drilling a big hole. You ABSOLUTELY need to use a drill press. Using a hand held drill would be a receipt for disaster.

You also need to clamp the blank down to the drill press table. A big drill bit can easily catch and rip the blank out of and/or thru your hand. Any sharp edges or corners on the blank will shred your hand.

The cheap “Steelex” brand Forstner bits currently available on Amazon for $2x work ok. The Amazon reviews vary quite a bit. Getting a good one is a crap shoot. I have gotten 2 winners recently.

Note: Amazon dynamically prices everything. I purchased a new 2-1/2″ Forstner bit last week for $20. Today the lowest price it will show me is $28.91. If I wait a few more weeks then the price will probably go back down to $20.

I have found that the “Sanding Wheel Brushes” from McMaster-Carr are a good alternative to the “3M Radial Bristle Discs” that I talk about in my “Power Carving Textures” blog entry.

The sanding wheel brushes are cheaper and last longer because they are tougher. They work good on raw wood. They are not as aggressive as wire wheel. They are more aggressive then 3M discs (not as soft). The bristles don’t break off like they do on the 3M discs.

I have all 3 grits available. I like the 180 grit best. The 120 grit is ok. The 320 grit is kind of to soft to be really useful.

You need to order an arbor for each brush. Www.mcmaster.com # 4875A14.

I want to document this here in my blog for my students.

The Nylon Mesh Sanding Rolls (aka Synthetic Steel Wool, aka Scotch Brite Pads) that I use are:

Carl Ford Course is

www.McMaster.com #4659A16 – Nylon Mesh Cushioned Sanding Roll for Aluminum, Soft Metal & Nonmetal, 15 Feet x 2″, Blending

Carl Ford Medium is

www.McMaster.com #4659A17 – Nylon Mesh Cushioned Sanding Roll for Aluminum, Soft Metal & Nonmetal, 15 Feet x 2″, All Purpose

Carl Ford Fine is

www.McMaster.com #4659A18 – Nylon Mesh Cushioned Sanding Roll for Aluminum, Soft Metal & Nonmetal, 15 Feet x 2″, Clean / Finish

All of the above are “Silicon Carbide” material. Catalog says they are for metal. I use them on wood.

They are all GRAY in color. To tell them apart, I do the following. I cut off a piece from roll. If fine then do nothing. If medium then clip 1/2″ off of ONE corner at 45 degrees. If course then clip 1/2″ off of TWO corners at 45 degrees.

Note: McMaster-Carr (www.McMaster.com) is an old school company. When you order something the order goes directly to the warehouse. They fill the order. Then the order goes to the office where they add the tax and ACTUAL shipping cost. Thus you DO NOT see the shipping cost until AFTER they ship something. You have to trust them to ship it to you at a reasonable cost, the old school way. I have always found their shipping cost to be reasonable. On 9/2019 it is roughly $10 for anything that fits in a 6″ x 12″ x 18″ box. In my experience, the weight has very little effect on the shipping cost. I live roughly 130 miles from their warehouse in Robbinsville NJ. You can find their closest warehouse at www.McMaster.com/returns.

Green and Maroon Stuff

I no longer use the green and maroon stuff that people may have seen me use in the past. They were “Aluminum Oxide” material (rather than “Silicon Carbide”). I gave up on these because they melt to easy. Hold them up to a piece running fast on the lathe, hit the corner or a sharp edge and they melt. It turns green! Ugg!!! No way to get rid of green.

If you want the old green it was www.McMaster.com #4659A13. I don’t known what the Maroon stuff was. I purchased it a very long time ago.

I Purchase from McMaster-Carr (www.McMaster.com)

Long ago, I gave up on the junk (oh, I mean stuff) from Home Depot, Lowes, etc. The quality varies to much by manufacturer. They are always changing their source. Some times it is good. Often it is junk. McMaster forces it’s suppliers to meet their quality specs or get lost.

I have found that the 2″ wide rolls from www.mcmaster.com are a lot better than the 6″ x 9″ pads from big box stores, etc. I don’t have to spend a lot time cutting the 6×9 pads up into small pieces to avoid wasting a lot of the pad. The stuff is already 2″ wide. Just cut off a 2″ or 3″ long piece and you are ready to go. When it is worn out or dirty you just discard a small piece. In the long run the rolls save money.

Real Steel Wool Sucks

I don’t use real steel wool. It gets caught in wood fiber to easy. Rusts, cuts your fingers off, etc.

Blue Towel

My “Blue Towel” that I use for buffing is a “Surgical Cotton Huck Towel”. You can get them on Amazon.

Beware: I got a big box of blue towels long ago from my father. He got them at an auction. The Amazon ones appear to be the same thing. But, I have never purchased the Amazon ones.

Carl Ford’s Sanding and Buffing in a Nutshell

I ONLY sand to 220 grit. Sand 80, 120, 180, 220 grit. Then I use Carl Ford “Medium” nylon mesh pad. Followed by Carl Ford “Fine” nylon mesh pad. Followed by buffing with “Blue Huck” towel.

Note: I have eliminated 150 grit sandpaper from my world. I use to sand 80, 120, 150, 180, 220 grit. Then, I decided that 150 grit was a waste of time. To close to 120 and/or 180. I no longer use 150 grit sandpaper. I now sand 80, 120, 180, 220 grit.

I use nylon mesh pads and buffing to replace sanding beyond 220 grit. If you catch the end of a nylon mesh pad, nothing happens! It DOES NOT scratch the work like the edge of 400 grit sandpaper will.

I may hold the nylon mesh pad up to the work while the lathe is running.

Often I cut a 2″ by 2″ square chunk of the nylon mesh pad and use it like a sanding disk with the lathe running. The nylon mesh just sticks to the hook part of any Velcro sanding mandrel you mount in a drill or any interface pad. I like to use a soft interface pad (1/4″ or 3/8″ thick foam pad).

After nylon mesh pads, I buff with a blue huck towel. I hold the towel up to rotating work on the lathe. AFTER I have folded up the towel into a square with no corners sticking out that can get caught by the lathe. Yea, its not completely safe. But, not all that dangerous.

Or I use an 8″ buffing wheel. The soft cotton “wax” wheel in the Beall Buffing System. Or 2 of www.McMaster.com #4820A12. I DO NOT use any wax on the wheel for any reason!

My blue towel replaces the old fashion trick of buffing with a handful of wood shavings. In the modern world we sand to much (to far). Buffing with wood shavings is often coarser than a 220 grit sanded surface and thus scratches the surface rather buffing it. My blue towel does not scratch the surface.

For more info see my “Great Polyurethane Finishes” blog entry.

]]> I recently took a WOW Factor master class with Nick Agar at

Arrowmont School of Arts and Crafts in Gatlinburg, Tennessee. June 9-16,

2019. Here are some photos of the work I created in the class.

I recently took a WOW Factor master class with Nick Agar at

Arrowmont School of Arts and Crafts in Gatlinburg, Tennessee. June 9-16,

2019. Here are some photos of the work I created in the class.

I had a great time at the class. Nick is a great instructor. I loved the environment at Arrowmont. The food was excellent. The turning studio is top notch.

Nick is well known for his Viking Sunset Bowls. This class was something different. It was all about creating turned wall pieces and sculptures from cut up turned forms. I also made some plates on my own to play with some of Nick’s decorating techniques.

I teach woodturning. But, I believe you should never stop learning. It’s time to roll over and die when you stop learning. Thus, I still take classes.

Here is the class description from the Arrowmont catalog.

During this master workshop students explore the potential of the wooden surface and what it offers makers. You will discover form and proportion and will create wall pieces, cut up-reconstructed sculptures, and turned and sculpted solid forms. Participants will utilize power carving, pyrography, airbrushing, and ceramic and metal effects using the instructors signature series paints (all made in the U.S.) and other paints to enhance their work to give it the WOW factor. Open to all skill levels, however basic skills at the lathe are needed.

Nick Agar has over 25 years of experience as a woodturner. He is a registered professional turner, co-author of the book Woodturning Evolution and an elected member of the Devon Guild of Craftsmen. Specializing in surface enhancement and renowned for his wall sculptures, his award-winning work often incorporates carving, airbrushing, ceramic and metal effects. Agar has inspired many woodturners with his work and has traveled across the world to demonstrate his skills. TURNINGINTOART.COM

I created 2 wall pieces in the class. I really enjoyed making

these. I am definitely going to be making more of these in the future.

I created 2 wall pieces in the class. I really enjoyed making

these. I am definitely going to be making more of these in the future.

Here is the 1st wall piece I created in Nick’s class. The wood is

really nice curly maple. 12″ square by 2″ thick.

Here is the 1st wall piece I created in Nick’s class. The wood is

really nice curly maple. 12″ square by 2″ thick.

The idea here was to turn and decorate square pieces and then cut them up. Nick suggested cutting them up in 1″ wide strips or into quarters. Then we could rearrange or skew the pieces.

After I turned the square piece, I decided to decorate it with airbrush stuff I learned from Nick. I love the way it came out!

I decided it was too nice to cut into strips. Thus, I cut it into quarters. The original piece is on the left in above photo. One of 16 possible arrangements is on the right.

I colored the piece with Chroma Craft Wood Dyes applied with an airbrush. I used some airbrush stencils from Nick, Amazon and Binh Pho.

Note: 4 pieces * 4 sides = 16 possible arrangements.

Here are two alternate arrangements of the 1st wall piece.

Here are two alternate arrangements of the 1st wall piece.

The piece is not done yet. I plan on mounting this piece on a black steel background that is roughly 3″ larger than the piece. I will install magnets on the back of each piece. This will allow people to rearrange the pieces to create their own image.

It looks better with a 1/4″ of space between the pieces. I just stacked them up for the photos. So, no space was possible. I am going to add spacers to the finial piece.

Note: Using magnets to mount sculptures on plinths (suspended in space) was one of the ideas Nick discussed in class. I decided to expand that idea to mount my wall pieces.

Here is the 2nd wall piece I created in Nick’s class. The wood is

Maple. 10-1/2″ square by 1-1/4″ thick.

Here is the 2nd wall piece I created in Nick’s class. The wood is

Maple. 10-1/2″ square by 1-1/4″ thick.

Nick suggested that we could remount and turn each quarter individually after cutting the main piece into 4 parts. I wanted to try out that idea. I also wanted to try a piece with out a lot of fancy airbrushing. Just let the beauty of the wood shine thru.

I was finishing this piece on the last day of class and got in to much of a hurry. I accidentally powered sanded the orange center on one of the 4 pieces. Then I had to try to cover it up by sanding all 4 of them. It didn’t really work out.

I colored the piece with Chroma Craft Wood Dyes applied with an airbrush. The Chroma Craft dyes are fast drying and DO NOT penetrate into the wood. Thus, I got way with, just sanding any dye over spray off the top surface to expose nice clean wood. I masked the junctions in circles with masking tape. That was a pain.

We started the class by creating sculptures from cut up turned

forms. We turned a 9″ round bottomed cereal bowl shape on the outside with

a small 2″ shallow bowl on the inside. Then we cut the bowl into slices

and experimented with carving, wood burning, coloring and finishing

techniques.

We started the class by creating sculptures from cut up turned

forms. We turned a 9″ round bottomed cereal bowl shape on the outside with

a small 2″ shallow bowl on the inside. Then we cut the bowl into slices

and experimented with carving, wood burning, coloring and finishing

techniques.

The photos show my 2 creations. The above photo on the left is the front view. The photo on right is the back view. I am really happy with the way the pieces turned out.

I cut my bowl into 3 slices. I never got around to using the center slice that contains the small 2″ bowl on the inside. It is NOT shown in the photos.

The green piece in photos is ash wood with power carved and burned textures. It was painted with copper and bronze reactive metallic paint. Some areas were painted with copper, others with bronze. Then it was aged with green patina aging solution.

The red, orange, and yellow piece is ash wood with power carved and burned textures. It was painted with red, orange and yellow Chroma Craft Wood Dyes. Then the back and some areas on the front were highlighted with Chroma Craft Viking Silver Chroma-Gilt.

Nick wanted us to mount our sculptures on a plinth with magnets. The magnets allow the pieces to be moved around and re positioned to create new configurations. I really liked the idea. But, the wimpy magnets I brought with me were not up to the task. My slices of ash were to heavy to be held up at the angle I wanted. I had to use dowels rather than magnets.

I made some 9″ hard maple plates. They were canvases on which I

could try some of the techniques demonstrated by Nick in the class.

I made some 9″ hard maple plates. They were canvases on which I

could try some of the techniques demonstrated by Nick in the class.

The plate on the left in the photo is Chroma Craft Wood Dyes applied with an airbrush. I used some airbrush stencils from Amazon and Binh Pho.

The plate on the right is Chroma Craft Black Web-Fx special effect paint, over Golden brand Iridescent Bright Gold acrylic paint, over Chroma Craft Blood Red Wood Dye.

You can see in the photo that some paint escaped under the masking tape that I used to mask things off. In the future I need to do a better job of masking.

I also made a viking style plate. I wanted to try Nick’s idea of

mixing different colors of Chroma Craft Chroma-Gilt on the same piece.

Some areas are say copper while others are bronze.

I also made a viking style plate. I wanted to try Nick’s idea of

mixing different colors of Chroma Craft Chroma-Gilt on the same piece.

Some areas are say copper while others are bronze.

I turned a 9″ hard maple plate and decorated it (cut groves in it) with my small and large Sorby Spiraling and Texturing tools.

In the above photos the front of the plate is on the left. The back is on the right. The back is darker than the front in real life. By design.

I kind of forget what I did here. I am not sure about the colors. Here is my best guess. The front is Saxon Gold and Antique Brass Chroma Craft Chroma-Gilt, over Green Verdigris Chroma Craft Chroma-Gilt, rubbed into the groves with a tooth brush, over Chroma Craft Black Wood Dye.

The back is Celtic Copper and Nordic Bronze Chroma Craft Chroma-Gilt, over Chroma Craft Black Wood Dye.

On the last day of class I made a platter (wide rim bowl). I liked

a platter with a white and blue rim done by another student. I wanted to

try something similar.

On the last day of class I made a platter (wide rim bowl). I liked

a platter with a white and blue rim done by another student. I wanted to

try something similar.

I took the piece home to finish at home when I did not have time to finish it in class. I got inspired and made another piece with a red background at home.

The platter in left photo is Blue and Black Chroma Craft Web-Fx special effect paint, over Rustolem flat white spray paint. With Golden brand blue and black acrylic paint, airbrushed on shading. The ugly brown marks in the bowl, showed up when I turned the bowl. They are in the wood. I was not happy.

The platter in right photo is Black Chroma Craft Web-Fx special effect paint, over Blood Red Chroma Craft Wood Dye . With Golden brand black acrylic paint, airbrushed on shading.

The black rim on both platters is black acrylic paint, applied with an airbrush.

Both platters are 9″ diameter, hard maple wood. The bottom of both platters is a roman ogee shape, natural wood color.

People are always asking me about face shields.

In A Nut Shell

I have found that face shields are HIGHLY PERSONAL. What one person

likes, others will hate!

Therefore you should try before you buy. Try at a class, school,

club or a friends house.

I have several different models of face shields in my studio. I

can never predict in advance what people will like.

What I Like

I started out with a simple “MSA Defender +” face shield from a

local store. Around $15. I still like this face shield and use it when

other people are around. I have several of these in my Studio and most

people like them or can live with them.

I primarily like this face shield because it is tough and there is

lots of space between the inside of the clear plastic and my face. Thus it

does not fog up easily and it does not fog up my glasses.

Unfortunately this face shield is no longer available. It was

discontinued. MSA does not make anything similar in a low price range.

If I wanted something similar today I would try the “Heavy Duty

Faceshield” #199210 from www.packwoodworks.com for $22 on 4/2019. I like

that Packard says ” The shield allows room for people who wear glasses”. I

hope this means the face shield will not come to close to my face. I also

hope it is not to heavy. I DO NOT own one of these and have never seen one

up close and personal.

The Sellstrom S32010 on Amazon for $30 on 4/2019 also looks good.

I DO NOT own one of these and have never seen one up close and personal.

The Safety Works Faceshield for $17 on 4/2019 on Amazon may be

similar to my MSA Defender + face shield. Is it ANSI rated? I DO NOT own

one of these and have never seen one up close and personal.

What My Students Like (The Rolls Royce of Face Shields)

Several of my students have and really like the “UVEX by Honeywell

S9500 Uvex Turboshield Face Shield Headgear with Black Frame” $22 with a

“UVEX by Honeywell S9555 Uvex Turboshield Clear Polycarbonate Replacement

Visor and Clear Lens with Dual Anti-Scratch/Anti-Fog Lens Coating” $28.

You have to order the headgear and clear lens separately. They

snap together.

You can get a cheaper lens with out all of the anti… crap for

$13. That is what I would go with. I don’t like anti… crap on my

glasses, etc. However, my students say the cheaper lens is not as good.

The cheaper lens is a “UVEX by Honeywell S9550 Uvex Turboshield Clear

Polycarbonate Replacement Visor and Clear Lens, Uncoated”.

All of the above prices are on 4/2019.

This is not the face shield for me. I like my cheap and dirty

ones. I have been wearing glasses for 50+ years. A little dirt is normal

and does not bother me. If you like to keep things clean and insist on a

really clean face shield then this UVEX face shield may be for you!

What I Don’t Like

Beware! I already told you face shields are HIGHLY PERSONAL. You

may like, what I don’t like. I known people who have and like all of the

following.

- I don’t like the yellow Apprentice Face Shield from Craft Supplies USA. To flimsy. To close to my face.

- I don’t like the blue 3M Face Shield from Craft Supplies USA, Amazon, etc. Way to close to my face. I have these in my studio. Only like 1 in 10 people like these. It’s built like a tank on the plus side. But, I still really don’t like it.

- I don’t like the Bubble Face Shield from Craft Supplies USA. Fogs up to easy due to closure at bottom of face shield. I need a face shield that has a big open space at the bottom to allow my hot breath out. I have these in my studio. Most people are not thrilled with these but can live with them.

- I don’t like any face shield with plastic below the clear part. i.e. near my chin. Chin guards, etc. Like, I already said. I need a face shield that has a big open space at the bottom to allow my hot breath out. Thus I don’t like any of the Uvex Bionic shields.

Powered vs Non Powered Face Shields (Open vs Helmet Face Shields)

All of the above are Non Powered face shields. There is no fan that

forces air over your face while wearing the face shield. Thus you have to

put up with any heat build up or fogging. Thus the face shields need to

be open at the bottom and/or top to allow air circulation. They are good

for beginners and/or light duty use.

Face shields that are part of a helmet (hard hat) are generally to

much trouble for beginners. But, after a few close calls, experienced

turners often favor them. When things come off the lathe, all hell can

break loose. Things (wood, etc) can bounce off the ceiling and come down on

top of your head, etc.

The helmet systems incorporate a small fan with a rechargeable

battery. This often adds way to much to the cost for beginners. The fan

forces a stream of air over your face. The air is normally filtered. I

am NOT saying “fresh” air. It is just filter air.

Powered Face Shields

The “Trend Airshield Pro” for $380 on 4/2019 currently is the only

game in town for less than $1000. I I DO NOT own one of these. I don’t

known what to say about these. Recently, Mark Baker gave it a positive

(but not glowing) review in the UK Woodturning magazine.

This style of unit has the batteries and filter up on the helmet

rather than down on a belt around your waist. The current model moved the

battery and filters to the back (rather than up front) for better balance.

I have (but have not used in a long time) a similar “3M Airlite”

with the battery and filter on the helmet up front. I had a love hate

relationship with this unit. I always forgot to charge the battery. Even

when I had a spare battery. The fan did not blow enough air to satisfy me.

I personally like lots (tons) of air! Your mileage may vary! This unit

was long ago discounted. The new 3M models start at over $1000.

Note: I don’t known if the new “Trend Airshield Pro” would move

enough air for me. I have never really tried it.

Eventually, I replaced the 3M Airlite with a “Triton Powered

Respirator”. It was a hard hat style helmet with the battery and fan on a

belt around your waste. This one supplied a little more air. But, still

not enough. Donning it was a pain. This unit has also been discounted.

Then I decided that all of these battery units were never going to

supply enough fresh air to satisfy me. I replace the battery box and fan

on the Triton unit with a 20′ long 1.5″ diameter light duty hose that was

driven by a 6″ in line duck fan. The fans they use for boosting air flow

in AC systems. This worked reasonably well. But, I got tried of that 1.5″

hose. It was hard to coil up and store. If I stepped on it, then I was

screwed.

I decided to bite the bullet, when I became a full time Woodturner.

I got an Allegro fresh air system. See next section.

What I Really Use

When I work in the studio by myself I use my Allegro fresh air

system. It brings in fresh air from outside via a small 3/8″ ID (5/8″ OD)

BREATHING air hose. Being restricted by an air line is not for everyone!

I like the fresh air! I wish the air line was a little more

flexible. But, it is tough. If I step on it, it’s not the end of the

world.

This is the kind of system they use in auto body shops for

painting, sand blasting and welding.

I don’t like the Trend Airshield, etc systems. The fans are to

wimpy for me. I like lots (tons) of COOL air!

Anything that involves “breathing air” is not cheap. 50 feet of

3/8″ air hose for tools, etc, is like $15. You don’t want to breath thru

some cheap plastic air hose that may still be out gasing toxic chemicals,

etc. 50 feet of certified 3/8″ breathing are hose starts at $100+. The

Allegro 9245 system in photo starts at around $1000. Its a low pressure

system.

I actually have over $2000 in my system. I have the bigger A-1500

pump rather than the A-300 pump in photo. I also have a low pressure air

cooler that I modified to fit in a chest freezer so I don’t have to supply

fresh ice daily. The air that comes out of my big pump is to hot for my

liking. I like to have my face bathed with a cool breeze. I have, an

external intake hose connected to the pump that bring in fresh air from

outside. Plus 100′ of hose, fittings, etc. It all adds up.

I am not interested in USED systems on Ebay, etc. I don’t want to

breath thru the same system that someone else has already used. I don’t

known if they kept it clean. I don’t know what they were using it for.

Toxic chemicals? Fine sand blasting dust? Etc.

If I had to do again I would get the A-750 pump. I got A-1500 pump

because I like lots (tons) of air! I decided the A-300 pump would probably

be to small for me. The A-1500 pump is to much! It runs hot because it

supplies lots of air. I have to vent almost 1/2 of the air at the pump.

It costs to much to run. The pump is hard to deal with because it is

really heavy.

Some day I may upgrade to the 3M M-107 Versaflo Helmet or the full

hard helmet from Allegro rather than the half helmet that I have.

An added bonus of this system is that it works great while sanding

or spraying paint. When I finish my work the rattle spray cans, etc of

nasty stuff, I don’t breath it and I can’t smell it!

I strongly recommend you try something like a “Trend Airshield Pro”

and decide you RALLY can’t live with it. Before you go with one of these

EXPENSIVE systems!

Note: Low pressure systems use a little pump like shown in above

photo. High pressure systems bleed the air off of a big gas powered air

compressor. The kind they use on construction sites to power jack hammers,

etc. You can only use a venturi effect air cooler on high pressure

systems.

]]>

Here is my “Craft Foam Projects Bowl Rim” tip that appeared in the “Tips” section on page 15 of the AAW February 2019 “American Woodturner” Journal.

Note: Click here to view PDF with Photos 1, 2, 3 referenced below.

I recently discovered sticky-back craft foam at my local craft store. It is 1/8″ (3mm) thick with a self-adhesive back. I purchased a couple of sheets for future use and have now found a good use for it. I’ve installed it on the face of my jumbo jaws to protect a bowl’s rim when reverse-chucked.

Simply remove the buttons from the jumbo jaws, cut the foam to shape with scissors, stick it on, and reinstall the buttons (Photos 1, 2). You can poke holes through the foam for various button placement as needed. I no longer need to fumble with trying to stick a paper towel between the jaws and my work when I’m concerned about damaging a finished surface (Photo 3).

The foam sticks very well but could be peeled off if necessary. I plan to leave the foam on the jaws indefinitely and replace it when it wears out.

Long ago, I also made my own buttons for my jumbo jaws out of some rubber corks that I purchased at the local hardware store. I drilled a hole through the corks and attached them with longer machine screws (also from the hardware store). I really like this solution. The deep dovetail shape of the corks holds the work securely.

Additional Information

You can purchase the rubber corks with a hole already thru them from www.mcmaster.com item # 9545K116 $8.33 per pack of 25 on 4/4/2019. The matching 30mm long 8mm screws are #92000A438 $8.15 per pack of 25 on 4/4/2019.

]]>

I am going to be teaching my 5 Day Woodturning Workshop class at the Peters Valley School of Craft in Layton NJ (in the Delware Water Gap National Recreation Area) on July 12-16, 2019. Their name for it is “An Exploration of Woodturning”.

Click here for more info or to sign up on the Peters Valley web site.

There is also more info in the Student Material List. Lots of info, not just a materials list. Click here for additional info.

There are no fixed projects in the above class. Students are free to do there own thing. Pick there own projects. Thus students can make a cake stand in the above class if they want. With or without the decoration. Or we can do similar decoration on a plate, bowl, etc.

Click on the photo below for more photos of my recent work.

Turning Smocks & Low Cost Alternatives

Over the years I have owned a number of different turning smocks.

Here are MY thoughts.

Sooner or latter every turner decides they need a turning smock.

Because, sooner or latter nature calls and you just don’t have time to shed

all the wood chips, etc. She who must be obeyed, has a no wood chips in the

house policy!

In A Nutshell

I like the AAW Turning Smock best. I absolutely HATE the blue color. The

dark grey one is not a whole lot better. But, I have found the lightweight,

short sleeve and roomy design works best. It is easy to get on and off. It

easily sheds wood chips.

I also hate the price! $65 on 2/2019. However, all the available

Turning Smocks are in the $60 range. See below for some cheaper

alternatives.

There are some cheaper look-a-lines. In better colors! See below.

Features

Features I look for the following in a turning smock. Basically everything the AAW turning smock has.

- Easy on/off

This implies I like jackets, rather aprons. I don’t want to fiddle around with tying and untying apron strings in the back when I need to go! - Something that will keep me cool in the summer.

Some people are naturally always cold, while others are always hot. I am the kind of person who never gets cold. So, I am looking for a turning smock that keeps me cool in the summer. If I am cold, I will add a layer under the smock. - Short sleeves.

I don’t like the elastic and/or knit cuffs on long sleeve turning smocks. Long selves violate my easy on/off criteria. - Loose fitting selves. Like the sleeves on AAW smock.

You need a loose fit to stay cool or if you want to wear something under a turning smock. - Simple tight (but not to tight) fitting collar.

You should be able to just zip the smock up and that’s it. No extra neck flap that you need to dork around with. The collar needs to keep the shavings from going down your back. You should be wearing a face shield that deflects away any shavings in the front.

I don’t like a knit collar that fits really tight in the front. It traps to much body heat. Makes me to hot. - Water resistant and breathable. NOT waterproof!

A soft lightweight brushed nylon fabric (like the AAW Turning Smock) that is water resistant (sheds water) is best. I don’t like waterproof fabric that does not breath. Waterproof gets to heavy and hot. You don’t really need waterproof! You just need something that sheds water and dries fast.

When I turned my first green log and all that water came flying out, I got a waterproof turning smock. It was good that winter. When summer came that smock had to go! It was just way to hot. After a couple of false starts, I eventually replaced it with an AAW smock and lived happily ever after. - Loose fit.

I don’t want something that clings to me like a knit shirt. I want something with room to add a shirt or what ever under it for warmth. Something that keeps me cool in the summer. - A flap over any pocket on the front. Or no pockets.

Any pocket on the front that does not have a flap over it will quickly fill up with wood shavings and become a huge pain in the back side.

I personally never use the pockets in my turning smocks. Thus, I would like to see manufacturers lower the cost of smocks by leaving out all the pockets on the front and back.

Note: You can close up a pocket in a shirt, etc with some masking tape. The tape keeps the wood shavings out. - Pockets on the back are a don’t care for me! Your mileage may vary.

I never use the pockets that are the back of turning smocks. Thus I don’t care if they exists. Pockets on the back do not need flaps. - Left or Right Zip. I don’t care. But, some people may.

In the US most men’s jackets are right zip. This means you grasp the zipper pull in your right hand. In other countries things may be left zip. i.e. you grasp the zipper pull in you left hand.

Most US turning smocks are right zip. Those made by or for European markets are left zip.

Three Types of Turning Smocks

Below is my not so humble opinion. There are basically

3 different types of smocks available. The field has narrowed in recent

years. Several manufactures have dropped out.

Note: Lee Valley no longer sells a long sleeve smock with a collar

flap. Packard now only sells an apron. No smock.

- The AAW Turning Smock and look-a-likes

Lightweight. With underarm vents. Good for people who are not looking for warmth. Want something that is cool in the summer.

I like the AAW Turning Smock best. I absolutely HATE the blue color. The dark grey one is not a whole lot better. But, I have found the lightweight, short sleeve and roomy design works best. It is easy to get on and off. It easily sheds wood chips.

I also hate the price! $65 on 2/2019. However, all the available Turning Smocks are in the $60 range. See below for some cheaper alternatives.

The Powermatic Turning Smock is an exact copy of the AAW Turning Smock in a nice mustard yellow color! Well, almost. It is left rather than right zip. It’s only $50 on 2/2019. I own one. The only retailer is Beaver Industrial Supply (BIS). https://bispowermatic.com/search/?cat=0&q=turning+smock

The Highland Woodworking sells a Shop Smock that also appears to be a copy of the AAW Turning Smock in a nice red color! I DO NOT own one of these and have never seen one up close and personal. $57 on 2/2019. https://www.highlandwoodworking.com/shopsmock.aspx - The Old Tan Craft Supplies USA Turning Smock

Mid weight. No under arm vents. Good for people who are looking for warmth and can live with being hot in the summer.

Craft Supplies USA makes two turning smocks. A new Black “Lightweight” one and a old Tan one. The old tan one is “mid weight tan twill material”, “100% polyester”. I would describe it as mid weight canvas. A lot heavier than the AAW smock. No underarm vents like the AAW smock.

$56 on 2/2019. I own one of these. I never wear it. It is way to hot for me. Please keep in mind that I am the type of person who never gets cold. - The New Black Craft Supplies USA Lightweight Turning Smock

$45 on 2/2019. I have only worn this smock once. I don’t like the way it hangs. It is to tight and cling fitting for me.

Low Cost Alternatives

- Red Kap 1P60 Convertible Collar Shirt Jacket

Price varies by size. Around $32 for 2XL. I own and like this lightweight jacket. Its really more like a shirt in weight. Tough, 65% polyester, 35% cotton fabric that sheds wood chips and dirt.

If you put some masking tape over the pockets it works well as a turning smock. I really like it for painting things in my studio.

It was a weird zipper. It zips down from the top. It is easy to use, after you get the hang of it.

It only comes in navy blue or black. But, the price is right!

Red Kap is a very old and well known manufacture in the automotive and uniform business. They make things in a ton of sizes. From small to ultra large.

Google “Red Kap 1p60” then look for the best price. I use “Automative Workware” when they have it. - Red Kap KP44 Men’s Zip Front Smock or KP43 Women’s Zip Front Smock

Price varies by size. Around $20 for 2XL. I DO NOT own one of these. It just looks good to me. However you will have to sew up or masking tape over the lower pockets. The price is right!

It only comes in navy blue or white.

Google “Red Kap kp44” then look for the best price. I use “Automative Workware” when they have it. - Green Cotton Welding Jacket

Cotton welding jackets have been around for a long time. They tend to be cheap. Around $30 for XXL.

No pockets on the front. Very tough yet flexible fabric. They are mid weight like the old Tan Craft Supplies USA turning smock. Often a light green in color.

The old one I have and like was made by Weldmark. Go down to your local welding supply store and find one you like. Or via Amazon, etc.

I found a green jacket on Amazon made by West Chester and a tan one made by Revco.

Vest

I have a Red Kap VT22 Quilted Vest that I wear in my studio under

my turning smock when it is cold. While I am waiting for the heater to do

it’s thing.

I like it. Not to thick, not to thin. $30 for L on 2/2019. The

price is right. Thus, if it gets screwed up, I don’t care.

I have a Large Red Kap VT22. It is a bit tight on me. But, fits

nicely under my XL AAW Turning Smock.

Google “Red Kap vt224” then look for the best price. I use

“Automative Workware” when they have it.

Jacket

30 years ago, I picked up a jacket at local used work wear place for

$10. Over the years, I learned to love this jacket for outside work.

It works good for chain sawing. It is not to heavy, not to light.

Reasonably warm, but not to warm. Etc, etc. The exterior is a tough fabric.

You can wash the jacket in any washing machine.

The slim looking jacket fits over my round figure. It does make me,

sort of look like a UPS man. But, who really cares if the jacket works.

After years of hard use I recently decided to get a new one due to an ugly

paint stain on my old one. 30 years latter, and they still make the same

jacket!

It is a Red Kap JT50 Perma-Lined Panel Jacket. $48 for XL on 2/2019.

It comes in a number of dark colors in both regular and long versions.

I like this jacket a lot better than my Carhartt jacket.

Google “Red Kap jt50” then look for the best price. I use

“Automative Workware” when they have it.

Pants & Shirts

Well, I have gone this far. I mind wells tell you about my favorite work

pants and shirts for my studio.

I like the Red Kap brand work pants and shirts. They are low cost,

tough, permanent press, and yet soft!

They are NOT like the old Sears or JC

Penny work pants and shirts that I hate. Because, they are so stiff they

stand up on there own. The Red Kap stuff also comes in better colors. You

don’t have to look like a gas station mechanic.

Red Kap is better than Carhartt in my not so humble opinion.

Pants

I have several pairs and like Red Kap PT10 Men’s Red-E-Prest Work

Pant”. $20 on 2/2019.

I really like these paints. Really tough, but still soft. I have a

very old pair of these that I have run into the ground. Lots of paint

stains and heard wear. No holes. These pants are like Dockers that don’t

wear out and get holes. They look great. A lot better than an ugly genes that

are to heavy, get holes to easy and cost a fortune.

The BEST thing about these pants is that you can get them in any

waist size with any inseam length!!!

I recommend you get these from “Automative Workware”

www.automotiveworkwear.com for any waist and inseam options. They hem the

pants if necessary. No extra charge.

Shirts

I have several Red Kap shirts that I like.

- Red Kap SB12BS Men’s Long Sleeve Industrial Stripe Work Shirt.

Like a dress shirt with a tough soft fabric. The fabric is a little heavier than a fine dress shirt. Around $19 on 9/2019. Price varies with size and color.

It comes in lots of colors. Some are real nice dress shirt colors. Others are ugly. The style number varies from SB12, to SP10 and SP14 based on the color. Go on the Red Kap or Automotive Workwear web site and look thru the colors. - Red Kap SP10EX Men’s Long Sleeve Microcheck Uniform Shirt

This is really a dress shirt. Not a work shirt. Lighter weight than the above. The microcheck fabric really makes this shirt look like an expensive shirt. Around $22 on 9/2019. - Red Kap SP74GB Men’s Long Sleeve Mini-plaid Uniform Shirt

I also really like this shirt. Really a dress shirt… Different colors. Around $26 on 9/2019.

All of the above shirts work ok under a short sleeve turning smock.

i.e. the fabric in the shirts is smooth enough so it does not easily catch

a lot of wood chips on the long sleeves, like cotton plaid shirts do.

Note: I DO NOT like the fabric in Red Kap SP14BY Men’s Long Sleeve Industrial Work Shirt (solid color, not striped) that I have. It catches wood chips easily. I don’t known if this applies to all colors or just the burgundy one that I own. ]]>

Here is my new photo setup. I started using it in 2018. I am very happy

with it.

I am now using "softbox lights" with a big graduated

black to white background. See photo above.

Previously I used a "Photo Tent". (See photo at the end of this

blog post.) Like recommended in AAW Symposiums, etc. It worked ok for

years. But then I decided I was tired of it. I did not like the lights all

that much. The tent was to small. I wanted to take photos of bigger things

and groups of things. Moving things around and positioning them inside of

the tent was a pain.

I looked around and decided that "softbox lights" were

the way to go.

I found some softbox lights on Amazon that I liked the looks of in my price

range.

They are "LimoStudio 700W Photo Video Studio Soft Box Lighting

Kit, 24 x 24 Inch Dimension Softbox Light Reflector with Photo Bulb,

Photography Studio, AGG814". $64 on 2/2019.

I like them.

The bulbs are big. Really big. 4" diameter by 9" tall.

I think big is good. They create lots of light that is soft from

the start because it does not all come from a small point source.

The bulbs are marked "eTopLighting photo bulb PB-85 120V

85W". No other markings. But, I think they are 6500K, daylight neutral.

I decided to get a big background so I could take photos of big things. I

like the background in photos to trail off from grey to black. Thus I use a

graduated black to white background.

Real photographers use a huge studio and let the light trail off

naturally. I don't have room for that.

My background is from Amazon. It is a "Flotone Vinyl Graduated

Background 43" X 67" Black to White #609". $74 on 2/2019.

There are lots of similar choices on Amazon. The price was more

than I would like. But, it was the best I could do.

I wanted a vinyl background so I cold wash it off when it got

dirty. However, that does not work well, because all these backgrounds

scratch really easily!

Note: I use the smudge tool in Photoshop to wipe out any scratches I

see on the background in my photos.

If you want to go cheaper you could just use some photo gray paper. Something that is a “Dove Gray” color. Something like “Savage Seamless Background Paper – #84 Dove Gray (53 in x 36 ft)”. $45 on 2/2019. Pick something that is the right width for your application.

Here is my new photo studio all stowed. I just roll the background up to

the ceiling. Then shove the lights, back out of the way. The table is part

of my photo set up. I just, leave it up and use it for other things.

Stowing things takes just a minute or two.

I made my own background roller. More about that latter. Before, I

made the roller, I used some big binder paper clips that hung the background from the

ceiling from some wires. I never put the background away and thus ended up

with scratches on it.

Note: I had to use the flash on my camera to get a photo of the

screen up against the ceiling. Err… I hate on camera flash! The light is

just way to harsh.

Here is my photo studio set up and ready to go.

The tall light is lighting the background and the over all scene.

The low light is my accent light. For this big group with lots of shiny

things, I have the accent light higher than normal. Later, I had to dork

around with the accent light, quite a bit to get rid of hot spots on that

glossy red plate.

I am using an old GOOD tripod, I got from a friend. A good tripod

is a must! A cheap tripod that moves around will drive you crazy.

The big black binder paper clips on the bottom of the background just add

some weight so it hangs down, out of the way. The paint cans, keep the

background from slipping off the table.

I adjust the height of the background and paint cans to get a nice

almost black background at the top of my photos.

I always take my photos in a dark room at night or on a cloudy day.

The photo lights are the only source of light. I don't want any other

sources of light that may reflect off my work, cast weird shadows or color

shifts.

Note: My good camera is on the tripod. I am taking this photo with

my old camera. Thus the quality of the photos in this blog entry, vary a

lot.

Here I have my camera set up ready to take a shot. I am going to live with

the hot spots in centers of bowls. They are virtually impossible to get rid

of in a group shot like this. The top of the red plate is still a little to

bright. I need to adjust my lights a little more.

In the viewfinder you can see the edge of my background on the left. For this

big group, I have to frame the photo based on top and bottom of all items

in the photo. I will cut left and right off latter in Photoshop. I also

leave some room on the top and bottom of shot for cropping in Photoshop.

My camera is an "Olympus TG-3". I really good camera. I

really like this camera. But, it is totally the wrong camera for this

application. But, it works just fine. This camera is designed to be really

tough for travel. It can be bounced off a concrete floor, dropped in a lake

or you can take photos in pouring rain. I have done most of these things.

It has a piece of glass in front of the internal folded lens to make it

really waterproof and thus totally the wrong camera for this application.

You can put this camera in manual mode. And lots of other stuff.

But, I never do, because it takes FANTASTIC photos in AUTO mode. Here I

have forced the flash off, set it to 8m (3216 x 2144) photo size (not the

max), 3:2 photo with a 1 second self timer, in auto mode.

The most important thing here is to FORCE THE FLASH OFF! No flash

for any reason come hell or high water with digital cameras.

A 1 second self timer is also real important. i.e. take the photo 1

second after I push the shutter button. Wait until, I let go and the camera

stops shaking then take the photo.

These days, any good point and shoot camera will get the job done.

Note: If I had a ton of money to waste then I would get a fancy OFF

CAMERA flash unit that I could ADJUST the brightness of. Then I would not

need to dork with my lights, etc. I could just use the flash. On camera

flashes like I have and can afford, do not work! Only one brightness (usually super bright) flashes like I have and can afford do not work!

Well, sort of the original photo. The original is 3316 x 2144, 1.46 MB. The

photo here has been down sampled to a reasonable size for the web.

Here is the photo I decided to go with. It is one of 10 or so,

taken from slight different angles and heights. I picked the best one.

If you are taking photos on Auto. Just

moving the camera a little often makes a BIG difference in how the light is

captured by the camera. Big differences in ISO, F stop, shutter speed,

white balance, etc.

I have found the best solution for ME is to take 10 or more photos

on AUTO and then pick the best one. Because, I don't really known what

I am doing. Taking photos on manual is a waste of time for ME. What F stop,

etc should I use? I have no clue. Once in a long while, I will take a photo

on Auto and then switch to Manual, where I tweak the settings that Auto

mode came up with.

I often rotate the pieces around a little or lot. The grain on some

pieces only looks great from one angle. Often not the angle I start out

with.

There are lots of scratches and some dust/dirt on the background in

this photo. Can you find them? I did not touch them up. I can't find

them even in the 1.46 meg original with out a lot of zooming.

Here I cropped the photo a little in Photoshop. Remove the edge of

the background on right. Leave a nice amount of space all around.

Auto Levels in Photoshop often does wonders. Makes the background

look better. Removes the dull gray cast. Auto levels did not do much to

this photo. I got the lights, etc right from the start. My TG-3 camera is

not the right camera for the job, but it does a pretty good job.

In Photoshop I did an Export, Save for Web. Saved the photo at 1600

px wide (1600 x 1160), 648K. Then I let Jalbum program down sample it to

828 x 600, 93K for my blog on the web. I normally shoot for original images

saved on my computer for the long term around 600K to 800K. If just one

object in the photo than I save at 800 px wide. If you save photos anywhere

on the web (Flickr, Google Photos, etc) they frequently get saved way below

this size.

Photoshop use to be head and shoulders above any thing else. That is no

longer true. The programs that now come with most digital cameras are

pretty good. They all support cropping. And most support some form of

"auto levels". You don't need Photoshop. Photoshop is a tool.

A tool with a HUGE learning curve. The programs that now come with digital

cameras are often a lot easier to use.

Note: This is one of the promotional photos for my Woodturning

Workshop class at Peters Valley on July 12-16, 2019. PV is calling it

"An Exploration of Woodturning". See

http://petersvalleyworkshops.bigcartel.com/product/an-exploration-of-woodturning

Like I said eariler. I ALWAYS take 10 or more photos from slightly different angles, heights and rotations of the subject. Then I pick the best one.

Here I am taking a photo of a lamp that will definitely not fit in my old photo tent. I have raised the background up to make this work.

Background Rolled Up for Storage

Background Rolled Up for Storage

Here is what my background looks like when rolled up for storage. The big

black metal binder clips add a little weight to the end of the background.

They make things a lot easier.

Notice that my roller is roughly 6" wider than my background.

I did this on purpose. I didn't want the edges of my background getting

all screwed up.

I made the roller out of 4" Sewer and Drain PVC pipe from

local big box store. I wanted a big diameter roller. I did not want the

background to get screwed up by being rolled to tight. I also, did not want

it to develop a memory and try to roll back up on it's own.

Note: Before, I

made the roller, I used some big binder paper clips that hung the background from the

ceiling from some wires. I never put the background away and thus ended up

with scratches on it.

Here you can see that I put 3 feet of heavy construction paper above my

background. This allows me to roll down the background further.

I REALLY like this roller because it has a clutch mechanism built

into it. It will not roll down on it's own while I taking photos, etc.

You have to pull on the white chain on the right to roll it up or down. See

next photo.

Clutch Mechanism for Background Roller

Clutch Mechanism for Background Roller

I purchased some roller brackets with a built in clutch mechanism. I

purchased "Good News Roller Blind Shade Metal Core Clutch Bracket Cord

Chain Repair kit 38mm" from Amazon. $9 on 2/2019.

I turned some pine wooden disks to reduce the 4" PVC pipe down

to the 38mm required by the rollers.

Here you can see that I cut the long slots off of the roller brackets in previous photo. Then I drilled my own new mounting holes.

Recently, I decided to start posting one photo per week of my recent work on the AAW’s Photo Gallery.

Go here to see some recent photos taken with my new photo studio set up: http://www.aawforum.org/community/index.php?media/albums/carl-ford.842/

Here is some advice I wrote for a new turner who has just purchased a Powermatic 3520C lathe. He was looking for advice on chucks, faceplates and a drill chuck. A threw in a little extra stuff.

Join the American Association of Turners (AAW)

You should join the AAW for there Journal magazine ASAP. The great mag easily pays for membership. It has lots of GOOD stuff for beginners and experience people. Go here: https://www.woodturner.org/page/MemberBenefits

You should join the AAW for there Journal magazine ASAP. The great mag easily pays for membership. It has lots of GOOD stuff for beginners and experience people. Go here: https://www.woodturner.org/page/MemberBenefits

You should also check out the AAW’s Woodturning Fundamental magazine and other stuff for new people. Go here: https://www.woodturner.org/page/FUNdamentals

Take A Class – Try before you buy!

You should take a class with a well known turner and/or a well known school. Try tools before you buy!

If you live in Colorado. Then take a class with Trent Bosch or a beginner class at Anderson Ranch. Or Google “woodturning classes”.

Turning Tools

I recommend taking a class and going with tool set used by your teacher/mentor. Otherwise my tool set is here: http://www.carlford.info/pages/jigs_tools/modern_tool_set/modern_tool_set.pdf

I recommend taking a class and going with tool set used by your teacher/mentor. Otherwise my tool set is here: http://www.carlford.info/pages/jigs_tools/modern_tool_set/modern_tool_set.pdf

Faceplates

Faceplates are a no brainier. The Oneway steel 4″ faceplate is the best out there. You don’t need stainless steel.

Faceplates are a no brainier. The Oneway steel 4″ faceplate is the best out there. You don’t need stainless steel.

Note: Oneway is the manufacturer name.

Avoid the cast iron, thin steel ones and aluminum faceplates on the market. They are OK for making Jam Chucks, etc. But, not for everyday work where you “ride the plates hard and put them away wet”.

The faceplate that comes with the Powermatic 3520C is an exception to the no cast iron rule. It is OK. But, to small. Only 3″. Get a 4″ one.

If you want to go big. I would wait and see. If you go there, I would go with a Oneway Versa Hub with a 6″ Versa Plate. You could go the Versa Hub & Plate route for the 4″ faceplate. However, removing the plate from the versa hub to put in screws tends to be to much trouble for a 4″ plate.

The info here is out of date on the tools stuff. Use my new modern tool set stuff on my blog. But the screws and faceplate stuff is still good here: http://www.carlford.info/pages/demos_classes/natural_edge_bowls/My_Ellsworth_Class.pdf

Drill Chuck (Jacobs Chuck)

Any of the “MT2 Drill Chuck” search results on Amazon will do. I would go with keyless. You don’t need high quality.

Currently (2/2019) the “PSI Woodworking Products TM32KL Keyless 1/2-Inch Drill Chuck with a 2 MT Mount” looks good for $38.

Look for a Rohm Supra chuck made in Germany if you want to waste some money on high quality you don’t need. There are some nice Rohm MT2 chucks on eBay. I just purchased one for $106 for my drill press.’

Note: Your Powermatic 3520C has a MT2 (Morse Taper #2) hole in the tailstock. The headstock is 1-1/4 by 8 threads with a MT2 hole.

Woodturning Chuck

Now we get to the more controversial subject of chucks. I will try to stick to the middle of the road and be brief.

Now we get to the more controversial subject of chucks. I will try to stick to the middle of the road and be brief.

Wood Magazine has a good intro to how chucks work and terminology here: https://www.woodmagazine.com/woodworking-tips/techniques/woodturning/four-jaw-lathe-chucks

Think about Jaws First

Sooner or latter most people decide they need/want more than one set of chuck jaws. Different size jaws, different shape, etc. Thus you should look at the cost of extra jaw sets BEFORE you pick a manufacture. Because you can NOT interchange different brands of chuck bodies and jaws. Vicmarc jaws only fit on Vicmarc chucks, etc.

Note: Vicmarc, Oneway, and Nova are the names of well known manufactures.

In general, extra Oneway chuck jaw sets tend to be cheapest. Then Vicmarc, Nova and then Easy Wood is out of this world expensive!

Oneway has a good jaw size and shape table here: https://oneway.ca/products-category/chucks

Chucks in a Nutshell

I agree with most of the professional turners that Vicmarc makes the best chuck bodies. The VM120 chuck is loved by many. However, all these people tend to be in the “dovetail jaws are best camp”. They tend to turn mostly dry wood. They often expand the chuck jaws into a recess in the bottom of a piece. Making generalizations like this is obviously going to elicit negative responses from some people. Go with a Vicmarc VM120 if you are in the dovetail jaws camp.

I turn mostly green wood from FRESHLY cut logs from trees. Fresh cut wood is soft and cuts like butter. Thus, I am firmly in the “profiled serrated jaws are best camp”. They work better on green wood. I ALWAYS clamp my jaws down on to the OUTSIDE of a tenon. Expanding into a recess in the bottom of a green wood piece almost always ends in disaster.

You can ONLY get serrated jaws from Oneway and they only fit on Oneway chucks. Thus I recommend the Oneway Stronghold chuck. It is also loved by many. I have 5 of them. I don’t like the smaller Talon chuck by Oneway. Go with a Oneway Stronghold if you are going to turn bowls or hollow forms out of green wood.

You can get dovetail jaws for Oneway chucks and extra Oneway jaws are cheapest. So you can have the best of all worlds with a Oneway Stronghold.

Dovetail Jaws verses Serrated Jaws

The advantage to dovetail jaws is you can removed a piece from a chuck and then remount it latter. It will still run almost dead true, with no wobble, etc. If and only if the wood has not warped. You can’t do this with serrated jaws that are clamped down over a tenon. You can if you expand the serrated jaws into a recess. However, dovetail jaws expanded into a recess are better.

You have to cut a dovetail for dovetail jaws. This can be a huge source of pain for new people. They make dovetail scrapers that will cut a “perfect dovetail”. However, they tend to catch. Then all hell brakes lose. Serrated jaws use a simple straight tenon that is easier to create.

Other Chuck Manufactures

I started out with a Super Nova chuck. I still really hate that chuck. It’s the chuck key that I really hate! The newer Nova chucks that use a simple Allen wrench key are OK. It’s hard not to like the low price of the Nova SuperNova2 direct thread chuck bundles on ebay. But, extra Nova jaws tend to be expensive. Some people love Nova chucks. They are not going to agree with me here. Sorry, it’s my blog.

The new kids on the block, like Hurricane chucks use to be cheap. No more! I see no reason to go with one of these new kids when the above well known manufactures are in the same price range.

Record brand chucks just splashed onto the scene in the US. They have existed for a long time in Europe where they are known for being made by Nova. Why not go with a cheap Nova on eBay?

Sorby and Axminster chucks are UK companies. They generally are not cheap in the US.

When it comes to chucks for Mini Lathes the field has gotten pretty muddy. I have not been keeping up. I still like the Barracuda2 Chuck by Penn State Industries. Mostly, I like the $149 price. I don’t known that it is any better than the look-a-likes by other manufactures.

There is no way on the face of the earth I want anything to do with these new “no jaw screws” chucks! Like, Easy Wood Tools, Easy Chuck, etc. Jaws need to be securely screwed on to a chuck! Otherwise they are just an accident waiting to happen. Sooner or latter jaws with out screws will come flying off and kill you.

Chuck Size

Bigger is always better in the US. Thus sooner or latter someone was going to come out with chucks bigger than the Vicmarc VM120 (5″) or Oneway Stronghold (4-1/2″). They are just trying to knock these chucks off their well earned thrones. You don’t need any of the bigger chucks. The extra weight will just be a pain in the ass when you take them on/off the lathe. It is the chuck jaw size of work ranges that makes a difference. Not the chuck body size. Well, maybe if someone made an 8″ chuck it would be better. But there is no real difference between a 4-1/2″ chuck and a 5″ or 6″ chuck.

Turning Smocks

Turning Smocks

Get yourself a turning smock before “he who must be obeyed” complains about wood shavings in the house. I like the AAW Turning Smock best. It’ll make a good valentines day gift!

Ric Rac Orchid Cactus Plate Bowl

Last month, I found these old photos that I never got around to writing up.

They are still relevant. Thus, here is my Ric Rac Cactus Plate Bowl.

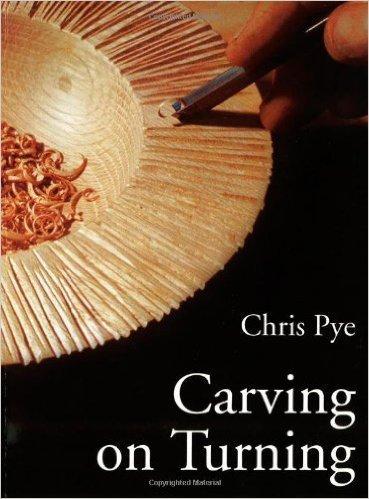

I created this plate bowl back in 2013. Not long after taking a

class with Al Stirt at The Center for Furniture Craftsmenship in Maine.

I used Al's pattern layout, and sgraffito process.

My inspiration for the pattern was my Ric Rac Orchid Cactus. See

photo above.

Note: I call a plate with a small blow in the center a "Plate

Bowl". Sgraffito definition "decoration by cutting away parts of

a surface layer (as of plaster or clay) to expose a different colored

ground".

Here is how I created the decoration on my plate bowl:

My inspiration for the pattern was my Ric Rac Orchid Cactus.

Boy this cactus was small back in 2013. It is now a big boy. I have

propagated it into numerous plants. See photo at end.

Here I have traced the leaf (stalk?) pattern onto the plate bowl with a

yellow water color pencil.

I am using a WATER COLOR pencil because I can easily remove it with

a wet paper towel. Water color pencils are easy to find in art supply

stores.

I turned the plate bowl out of maple wood. Then, I prepped it with

(one or two coats, I don't remember) of black acrylic gesso paint. I

thined the gesso a little with some water. The gesso dries flat. I like to

use a good quality gesso. I use either Golden or Liquitex brand.

Latter, I will top coat the finished piece with a semi gloss or

gloss finish. For now, I just want a nice flat surface I can draw on.

After the gesso dried, I sprayed it with flat lacquer to toughen up

the gesso and make it water proof. In 2013, I probably used Deft brand flat

lacquer. Sprayed on from a rattle can. Today (in 2019) I would use 2 to 3

VERY LIGHT coats of Krylon brand "Matte Finish 1311". Matte is

the name of the finish. It dries fast and makes a great surface to work on

top of.

Transfer the Pattern to a Template

Transfer the Pattern to a Template

After I create a pattern that I like, I need to replicate it over and over

on the plate. I do this by creating a template.

I get some thin, yet rigid, see thru plastic sheet from local craft

or fabric store. Quilters use this stuff. Low cost. You can get it with or

with out a grid on the plastic. It looks like I had the grid stuff back in

2013. I now prefer it, with out the grid.

I trace the pattern I like onto the plastic with a run of the mill

#2 pencil. Click on the photo for a better view.

I cut out the template with an X-acto knife.

Note: Should I call it a Template or Stencil? I am going with

template.

Here I am testing out the template. It looks good.

Notice that I discarded the part in the middle. The part that most

people would keep. I want the outline of the shape. Not the shape. Why,

will become obvious in the next couple of photos.

Now I need a way to rotate the template around the center of the bowl and

position it at the same angle.

The photo shows the gizmo, I came up with. I cut a piece of plywood

that fits in the center bowl. Then I attached the plywood to a chunk of

scrap metal.

Then I taped the template to the metal with some masking tape. Now,

I have a template that can be rotated to any position on the bowl.

This gizmo works on any outside shape plate (square, oval or round)

with a round bowl in the center (or off center).

Now I play around. I move the pattern around and decide what visually looks

best. How close together, do I want the leaves? How many leaves fit nicely

all the way around the plate?

I can use my yellow WATER COLOR pencil to temporarily draw things

on and see how they look. Because I can easily erase the water color with a

damp paper towel.

I decided, I wanted 7 leaves. 7 is an odd number. Things often

occur in nature in odd numbers. 3, 5, 7, etc. Odd numbers often look best.

7 leaves allows the widest part of the leaves to almost touch.

About 3/16" apart. The pattern will visually fill up most of the

plate. But, not to much! See photos below.

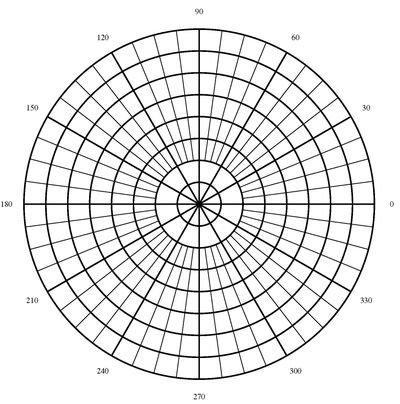

Now it is time to make some reference marks that will allow me to evenly

space the pattern.

360 degrees / 7 leaves = 51.43 degrees. Thus, I need a reference

line every 51 degrees and then fudge the last one a little if needed to

make it look good.

I used my protractor to mark the first 51 degree spot. Then, I just

attached the protractor to my gizmo and rotated it, to make a mark every 51

degrees.

I made all the marks with a WATER COLOR pencil so I can easily

erase them latter with a damp paper towel.

This photo shows the 7 reference marks.

Why didn't I use the index in the lathe? Well, I find indexes

built into lathes, are generally, completely and totally useless in my not

so humble opinion! They are way to hard to use. They are often buried

inside and/or hard to see. They have way to many holes. I only need like

12! Counting every fifth hole or what ever is for the birds! It never comes

out right! Are they zero or one origin? Err……

In this case, there is no doubt, any lathe index is completely and

totally useless! I want 7, an odd number. Lathe indexes are always even

numbers!

Here I have taped the template to my gizmo. I am rotating the gizmo. Lining it up on my reference marks. Drawing on the pattern with a WATER COLOR pencil.

This photos shows my circle T-Square. I got this from Al Stirt. The

t-square has been adapted to ride on the outside edge of a circle.

In this case, my outside bowl is circular (rather than square or

oval) and my inside bowl is in the center, thus I could have used this

rather than my gizmo.

I could have just taped my template to the t-square and then

rotated the t-square.

Here I have started carving in the pattern with a 1/8" ball cutter

(burr) in a rotatory tool.